|

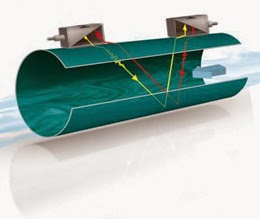

| Transit-time difference Method (courtesy of FLEXIM) |

The Transit-Time Difference method exploits the fact that the transmission speed of an ultrasonic signal depends on the flow velocity of the carrier medium.

Similar to a swimmer swimming against the current, an ultrasonic signal moves slower against the flow direction of the medium than when in flow direction.

The Measurement Principle

|

| Diagram of FLEXIM transit-time difference flow meter design. |

The transit-time of the ultrasonic signal propagating in the flow direction is shorter than the transit-time of the signal propagating against the flow direction. A transit-time difference, Δt, can thus be measured and allows the determination of the average flow velocity based on the propagation path of the ultrasonic signals.

An additional profile correction is performed by proprietary FLEXIM algorithms, to obtain an exceptional accuracy on the average flow velocity on the cross-section of the pipe - which is proportional to the volume flow.

Since ultrasounds propagate in solids, the transducers can be mounted onto the pipe.

The measurement is therefore non-intrusive, and thus no cutting or welding of pipes is required for the installation of the transducers.