- Pneumatic actuators: Pneumatic actuators use compressed air to move the valve stem and adjust the position of the valve disc. They are popular because they are relatively inexpensive, easy to install, and require minimal maintenance.

- Electric actuators: Electric actuators use an electric motor to drive a mechanical linkage that moves the valve stem and adjusts the position of the valve disc. They are typically more precise than pneumatic actuators, and can be controlled by a variety of electronic devices such as process controllers, programmable logic controllers (PLCs), and distributed control systems (DCS).

- Hydraulic actuators: Hydraulic actuators use a fluid under pressure to move the valve stem and adjust the position of the valve disc. They are typically used in large valves or high-pressure applications where high force is required.

- Electro-Hydraulic actuators: This type of actuator is a combination of electric and hydraulic actuator. The electric motor operates a pump that generates the hydraulic pressure which is then used to move the valve stem and adjust the position of the valve disc.

- Smart actuators: Some modern actuators have the capability of communicating and self-diagnostics which is important for advanced control systems, These smart actuators are typically interfaced with digital control system which enables to monitor, control, and adjust the performance of the valve.

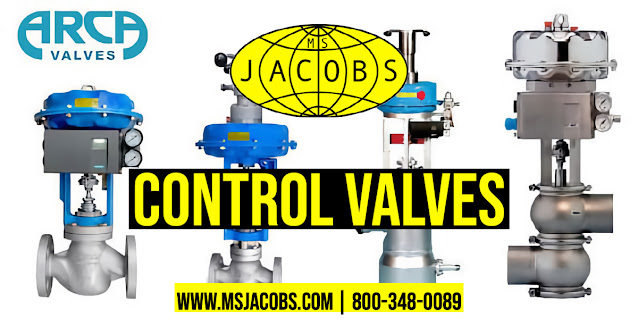

Sponsored by M.S. Jacobs & Associates, a manufacturer’s representative and distributor of industrial instrumentation, control valves & process controls. Located in Pittsburgh, Pa. and covering Western Pennsylvania, West Virginia, and New York. Representing top lines in pressure, temperature, level, flow, analytical instruments and industrial valves.

Telephone: 800-348-0089 or MSJacobs.com

Globe Control Valves

Electric Heat Tracing for Pipes, Tanks, and Vessels

BriskHeat Electric Heater, Control, and Insulation 2022-23 Product Catalog

The Rotork YT-3400 Smart Valve Positioner

New Manufacturer Partner - ARCA Valves

M.S. Jacobs & Associates, Inc. is happy to announce its appointment as an official ARCA Valves distributor. ARCA Valves has garnered global renown for its innovative technology and established quality since its foundation over a century ago. ARCA's pneumatically and electrically operated control valves provide high value for many industrial applications. They meet the rigors of many challenging applications in various industries, including power plants, chemical plants, pharmaceutical and food processing, and steel mills.

Thanks to its excellent vertical integration, ARCA's manufacturing process is versatile and has a high supply capacity. ARCA manufactures and supplies valves with nominal diameters up to 48" and pressure ratings of over 5,000 PSIG for high-pressure applications.

ARCA's technological leadership is built on 90 years of expertise and ongoing innovation, evidenced by several patents. The factory's output, which is of the highest technical quality and certified to appropriate quality standards, ensures a high level of dependability.

For more information, contact M.S. Jacobs by calling 800-348-0089 or visit https://msjacobs.com.