|

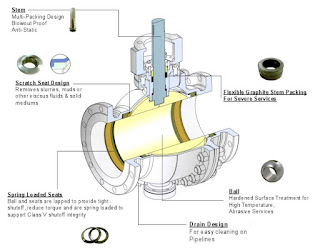

| Three piece industrial ball valve, manually operated Image courtesy of Duravalve, Inc. |

During valve operation, the ball is rotated through a ninety degree arc from a fully closed to fully open position. When fully closed, the opening in the ball faces the sidewalls of the valve body and is cut off from the fluid by seals that secure the ball in place and prevent fluid flow around the ball. As the valve stem is rotated toward the open position, the cross sectional area of the opening is increasingly exposed to the fluid flow path until the open area through the ball is aligned with the flow path in the fully open position.

Here are some general installation and removal guidelines for ball valves.

- Verify whether the valve is unidirectional or bidirectional. If valve function is limited to a single direction, make sure the inlet and outlet ports are properly oriented to the piping system flow direction.

- Adequate access for handle movement, along with an operator's hand, should be confirmed prior to installing the valve.

- Ball valves will function in any orientation.

- If automated with an actuator, maintain sufficient clearance around the valve and actuator to provide adequate maintenance access.

- Keep the installation area free of debris and dirt. Protect any valve parts that are removed or are awaiting installation. Avoid introducing any foreign matter, dirt or debris into the valve.

- Valves may have any of a number of connection methods, including threaded, flanged, or socket weld. Disassembly of the valve may be appropriate when installing some types, especially socket weld. Care should be taken to avoid any damage to the ball surface, seals, or sealing surfaces. Scratches and nicks can produce leakage when the valve is reassembled.

- If disassembling a currently installed valve, verify that the piping system is not under pressure prior to starting. Cycle the valve through open and closed positions a couple times to relieve any pressure that may be retained in the valve body.

- Follow all manufacturer recommendations for applied torque on any fasteners.

- When a ball valve is disassembled, for any reason, it may be a good time to replace seats.

- Leak check final installation. Tighten packing gland nut to eliminate leaks at the stem.

These are general recommendations. In every instance, a review of the valve manufacturer's specific instructions prior to starting installation or service is good practice. Share your fluid control challenges with industrial valve specialists. Leverage your own knowledge and experience with their product application expertise to develop effective solutions.