Sponsored by M.S. Jacobs & Associates, a manufacturer’s representative and distributor of industrial instrumentation, control valves & process controls. Located in Pittsburgh, Pa. and covering Western Pennsylvania, West Virginia, and New York. Representing top lines in pressure, temperature, level, flow, analytical instruments and industrial valves.

Telephone: 800-348-0089 or MSJacobs.com

Analynk Wireless Overview Video - Wireless Connectivity For Process Measurement and Control

M.S. Jacobs handles the Analynk line of industrial wireless products. Available for use in almost every industrial environment, including those rated hazardous, Analynk products enable extension of your industrial WiFi into hazardous areas. Other products enable radio links between process measurement and control locations on a local, remote, or global scale. The video provides a summation of the company's product offering.

Share your wireless connectivity challenges with product application specialists and work together to develop effective connectivity solutions.

Thermoelectric Generator for Remote Site Power Generation

|

| Thermoelectric generators at remote site Courtesy Gentherm GPT |

A thermoelectric generator is one of several solutions to consider as a power source at a remote location. Each generation technology has a set of attributes making it more or less desirable for an application under consideration.

Thermoelectric generators convert heat directly into electricity using a fuel source for heat, a hermetically sealed thermopile, cooling fins, and no moving parts. The TEG delivers a low maintenance and cost effective solution for remote power requirements, having operational and cost benefits over engine driven generators, batteries and solar sources for many applications.

The short document below provides an overview of thermoelectric generator operation and application. Talk to a product specialist about your need to power and communicate with a remote site. A thermoelectric generator may be an option you had not considered, but may prove to be the best solution.

Installing a Clamp-on Ultrasonic Flow Meter

|

| Ultrasonic flow meter with clamp on sensor Courtesy Flexim |

Producing consistently accurate results with an ultrasonic flow meter depends heavily on a proper installation. Flexim, a globally recognized leader in the manufacture of ultrasonic flow meters, provides us with a video that steps through the installation process, with recommendations and guidance along the way.

Flexim manufactures a full range of ultrasonic flow measurement equipment and instruments for industrial and commercial applications. Share your flow measurement challenges with process measurement experts, combining your process knowledge with their product application expertise to develop effective solutions.

Monitoring Generator Sets in Standby Mode Increases Reliability

|

| Remote Monitoring of Electric Generator in Standy Mode |

Acromag, a globally recognized manufacturer of signal conditioning equipment, has authored an application note outlining the extent of remote monitoring that should be employed and how to accomplish it.

The application note is included below. Share your process signal conditioning and transmitting challenges with product specialists, combining your process knowledge with their product application expertise to develop effective solutions.

In-Line Thermal Flow Meters

|

| In-line thermal dispersion flow meters Thermal Instrument Company |

Two sensors are exposed to the heat transferring effect of the flowing media. When the media composition is known, the mass flow can be calculated using the meter reading and the pipe cross sectional area. One of the flow meter sensors is heated, the other is allowed to follow the media temperature as a reference. The heat dispersion from the heated sensor is measured and used to calculate mass flow.

Some positive attributes of thermal dispersion flow meters:

- In-line and insertion configurations available to accommodate very small to large pipe sizes

- Rugged Construction – Stainless Steel with available protective coatings and other specialty metals

- No moving parts

- Measure liquid or gas in general, sanitary, and ultra pure applications

- Measurement not adversely impacted by changes in pressure or temperature

- Wide range of process connections

- In-line versions provide unobstructed flow path

- Wide turndown suitable for extended flow range

- Back up sensors for extended life

- Sensors do not contact process media

- Flow and total flow measured

- 4-20 mA output interfaces easily with other instruments and equipment

Share all your process measurement challenges and requirements with product application specialists, combining your process knowledge with their product application expertise to develop effective solutions.

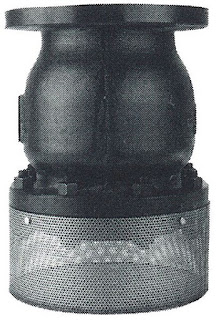

Foot Valves: Basic, Hidden, Essential

|

| Foot valve showing inlet filter screen Colton Industries |

For industrial applications, there are numerous versions of foot valves available in varying sizes, capacities and materials of construction. The function of the valve is simple, so the key selection criteria can be focused on features that will contribute to longevity and reduce or eliminate any maintenance burden.

The data sheet below provides some good illustrations of a foot valve and how it is installed. Share your fluid processing and control challenges with application experts, combining your process and facility knowledge with their product application expertise to develop effective solutions.

Pneumatic Volume Booster Function

|

| Pneumatic Volume Booster Fairchild |

The general purpose of a volume booster is to provide a relay between a system with low flow volume and one with higher volume requirements. A typical example is a pneumatic actuator. The flow available through the pneumatic signal line may be insufficient to deliver the response rate desired from the pneumatic actuator. A volume booster, with control over an independent air supply, solves this challenge with increased flow volume at the same pressure as the control signal.

Volume boosters are simple in operation. The input signal applies force to one side of a diaphragm, the output pressure to the other. An imbalance between the two applied pressures will cause the diaphragm to move, changing the position of the valve and the outlet pressure until the two forces are again in balance. Little maintenance is required when the units are properly installed and supply air is of good quality.

The unit pictured is from Fairchild, a well recognized manufacturer of industrial pneumatic components, and provides a 1:1 ratio. There are some key points in the selection process, so reach out to a product specialist with your pneumatic system challenges and requirements. Combining your process and facility knowledge with their product application expertise will produce effective solutions.

Subscribe to:

Comments (Atom)