|

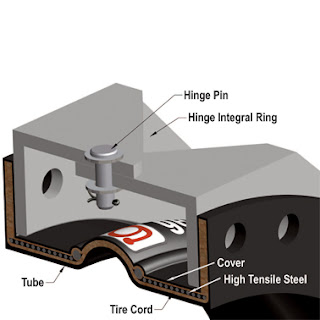

| Cutaway view of hinge restrained expansion joint |

Process piping of sufficient size or extent can require allowances be made for expansion of the piping material in the installed location. The design criteria will include factors that impact the expansion of the piping components, as well as the relationships between the piping and elements of their supporting structures. Expansion can produce substantial movement of pipe sections which must be accommodated by the supports and the piping itself.

One manufacturer, General Rubber Corp., provides a hinge restrained rubber expansion joint that is designed to allow angular rotation of a piping section within a single plane. The expansion joint isolates the movement of one pipe section from its adjacent connected section. The assembly is comprised of a pair of pin connected hinge plates attached to the expansion joint hardware. The company further describes the unit construction and function...

The hinge assembly must be designed for the internal pressure thrust forces of the system. They can be used in sets of two or three to absorb large lateral movements in a single plane. This optimally designed arrangement is an effective solution for absorbing large axial thermal movements from an adjacent pipe run. Its spool type body is constructed with full rubber flanges, a high-grade leak proof-tube, multiple layers of high-strength tire cord, high tensile steel reinforcement and a seamless cover. They are commonly used when the support structure or adjacent equipment have load limitations. The economic benefits of this arrangement include a smaller system footprint with far fewer anchors and guides.The video included below provides an animated illustration of how the expansion joint functions. More information is available from product specialists, with whom you should share your process piping system challenges.