|

Industrial process control can be confronted with

hazardous, corrosive, or other fluids containing

suspended solids. |

Industrial process control can involve the manufacture, storage, or transport of almost any imaginable fluid. Media can range from water to concrete, hydrogen gas to steam, and anything in between or outside of those boundaries. Valves are the favored control device for regulating fluid flow and they are available in uncountable varieties, each with particular aspects making them more of less suitable for a particular media or application.

Most industrial valves consist of a body, a stem, and some form of flow obstruction which is located within the media flow path. Operation of the stem repositions the obstruction to allow or block the flow. All of these valve types have a defined sealing surface where the obstruction contacts the body. They also have additional seals where the stem penetrates the body. These design features, while providing certain functions and application advantages, also add to the operational complexity and parts count for the valve.

There is a valve type with a simple operating principle that provides superior performance when the application involves certain media characteristics. It is called a pinch valve, and here is where it excels.

- Resistance to abrasion and corrosion from slurries or fluids containing suspended solids and the ability to provide tight shutoff around particulates

- Media and environmental temperature range -40 deg F to +300 deg F

- Low to moderate operating pressure

- Flow regulating capability and tight shutoff

- Non clogging

- Straight through full bore design with minimal flow resistance

- Isolation of the valve body and workings from the media

- Low parts count, low maintenance, easy repair/replacement

|

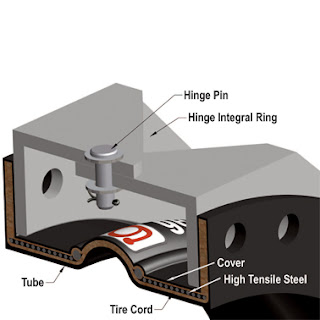

Cutaway view of manually

operated industrial pinch valve |

A pinch valve consists of a sleeve, through which fluid flows, and a means to compress or "pinch" the sleeve to reduce the open area inside the sleeve. The sleeves are most often fabricated from elastomers with various types of fiber reinforcement. Closure is commonly achieved through movement of one or two bars to squeeze the sleeve, providing throttling or positive closure. The flexibility of the sleeve material allows for tight shutoff, even with fluids containing suspended solids. The valves can be coupled with electric or pneumatic actuators and are available with industry standard connections. One valve variant has a body that can be pressurized to close the sleeve, without the need for a separate actuator. Pinch valves are available with and without an enclosing body.

You should be familiar with the capabilities and forms of this unique valve type. When confronted with certain application challenges, a pinch valve can be a superior solution. I included a product line data sheet from one manufacturer,

General Rubber Corporation, so you can see all the different variants that are available. You can get even more information, or start a conversation about any of your process control challenges, by contacting a

product specialist.