|

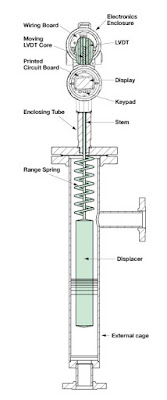

| Electronic Displacer Transmitter Courtesy Magnetrol |

Magnetrol, a globally recognized leader in the design and manufacture of level measurement instrumentation, has produced a comparison of displacer transmitters and differential pressure transmitters applied to liquid level measurement.

What is a displacer transmitter?

Displacer transmitters are considered a direct means of level measurement.

Quoted from Magnetrol website page on displacer transmitters...

Electronic displacer level transmitter technology operates by detecting changes in buoyancy force caused by liquid level change. These forces act upon the spring supported displacer causing vertical motion of the core within a linear variable differential transformer.

As the core position changes with liquid level, voltages are induced across the secondary windings of the LVDT. These signals are processed in the electronic circuitry and used to control the current in the 4-20 mA current loop. The enclosing tube acts as a static isolation barrier between the LVDT and the process media.

How does a differential pressure transmitter measure liquid level?

Liquid level can be inferred through the measure of the pressure generated by the column of liquid in a tank or vessel. The measurement device must be calibrated for the specific gravity of the measured media in order to attain reasonably accurate results. There are a number of installation arrangements of differential pressure transmitters that will accommodate tanks open to atmosphere, closed pressurized tanks, and more.

The comparison is included below and provides some interesting points to consider. Share your level measurement application challenges with a product application specialist. Combining your process experience and knowledge with their product application expertise will produce the best solutions for your process measurement needs.