Ashcroft, Inc. manufactures a wide variety of electronic and mechanical pressure and temperature instruments are produced in this facility under the brand names of Ashcroft®, Heise®and Weksler®. Ashcroft products are recognized as best-in-class for pressure and temperature measurement, including gauges, thermometers, switches, transducers, transmitters, instrument isolators and diaphragm seals and control and calibration equipment.

The Product Ordering Handbook includes descriptions, part numbers, and specifications for all Ashcroft products.

Download the Ashcroft Ordering Handbook from the M.S. Jacobs web site here.

Sponsored by M.S. Jacobs & Associates, a manufacturer’s representative and distributor of industrial instrumentation, control valves & process controls. Located in Pittsburgh, Pa. and covering Western Pennsylvania, West Virginia, and New York. Representing top lines in pressure, temperature, level, flow, analytical instruments and industrial valves.

Telephone: 800-348-0089 or MSJacobs.com

Showing posts with label Western Pennsylvania. Show all posts

Showing posts with label Western Pennsylvania. Show all posts

Pipe, Valve, Fitting and Instrument Insulation: Silver Series by BriskHeat

The BriskHeat Silver-Series insulators are a configurable insulation system made of durable, high-temperature cloth that allows for very easy installation and removal. The Silver-Series provides 1” thick, needle-punched fiberglass insulation with hook & loop closures. The innovative design applies very efficient thermal insulation for hot or cold pipes, valves, instrumentation, tanks and vessels in industrial and commercial environments. Custom designs can be manufactured for unique requirements.

For more information, contact M.S. Jacobs & Associates.

https://msjacobs.com

800-348-0089

New Product Alert: WIKA High Pressure Valves

High-pressure valves are being added to the WIKA portfolio of pressure, temperature, level, flow and WIKA USA includes ball valves, needle valves, check valves, and instrument manifold valves with pressures from 15,000 psi to 60,000 psi. in 1/4" to 1" sizes.

High-pressure valves are being added to the WIKA portfolio of pressure, temperature, level, flow and WIKA USA includes ball valves, needle valves, check valves, and instrument manifold valves with pressures from 15,000 psi to 60,000 psi. in 1/4" to 1" sizes.force measurement. With the acquisition of SAMI Instruments S.R.L. by the WIKA Group is expanding its portfolio of specialty valves. The new portfolio of standard and specialty valves available through

Products include:

- Medium and High Pressure Needle valves and Manifolds

- Medium and High Pressure Ball Valves

- Medium and High Pressure Soft and Ball Check valves

- Medium and High Pressure Fittings

- Medium and High Pressure Adapters

How They Work: Magnetically Coupled Liquid Level Indicators (Mag Gauges)

Magnetically coupled liquid level indicators are in widespread use throughout today's process industries.

Originally designed as an alternative to site and gage glass devices, MLI’s are now commonly utilized in both new construction and plant expansions. Orion Instruments magnetic level indicators are precision engineered and manufactured to indicate liquid level accurately, reliably, and continuously.

As shown in this video, a float designed for the specific gravity of the process liquid travels inside the MLI chamber tracking the rise and fall of the process media.

This float contains an internal magnetic assembly that couples with the external visual indicator. The individual “flags” or “flippers” rotate 180 degrees as the level rises and falls, indicating the position of the liquid inside the MLI, and therefore, indicating the level of the liquid in the vessel.

These units are completely sealed and require little to no periodic maintenance. MLI’s also eliminate fugitive emission and glass breakage concerns common with site and gage glasses.

To complement these products, level switches and transmitters are available to further expand the control and alarm capability of the MLI.

For more information on magnetic level indicators, contact: M.S. Jacobs and Associates by calling 800-348-0089 or by visiting https://msjacobs.com.

The FLUXUS® F/G721: Non-intrusive Liquid and Gas Flow Measurement

The FLEXIM FLUXUS® F/G721 offers non-intrusive flow measurement of virtually any kind of liquid or gas, from the smallest tubing to the largest penstock, independent of the pressure inside the pipe and over a very large temperature range. Due to its advanced technology, the measurement is unaffected by solid or gaseous entrainments or gas wetness and distinguishes itself by its unrivaled turndown ratio: Even low flows down to only a few liters per hour can be recorded accurately.

As the flowmeter of choice for a very wide range of applications in virtually any industrial sector, the FLUXUS® F/G721 is available with two different enclosure types: aluminum housing for standard applications and stainless steel housing for operation in highly corrosive environments. Both can be used in explosion hazard areas (ATEX, IECEX Zone 2).

For more information, Contact:

M.S. Jacobs and Associates

https://msjacobs.com

800-348-0089

Magnetic Level Indicators (MLIs)

Magnetically coupled liquid level indicators, or MLIs, are in widespread use throughout process

industries. Originally designed as an alternative to sight and gauge glass devices, the MLI is now commonly used in both new construction and plant expansion. They are engineered and manufactured to indicate liquid level accurately, reliably, and continuously. These units are completely sealed and require no periodic maintenance. MLIs also eliminate vapor or liquid emission problems common with sight and gauge glasses.

APPLICATIONS

- Feedwater heaters

- Industrial boilers

- Oil/water separators

- Flash drums

- Surge tanks

- Gas chillers

- Deaerators

- Blowdown flash tanks

- Hot wells

- Vacuum tower bottoms

- Alkylation units

- Boiler drums

- Propane vessels

- Storage tanks

Download a full Orion Instrument capabilities brochure here. For more information on Magnetic Level Indicators, contact M.S. Jacobs & Associates by calling 800-348-0089 or visit their web site at https://msjacobs.com.

Just in Time for Winter - BriskHeat Freeze Protection Planning Guide

Anticipating freezing conditions and protecting buildings, equipment, and grounds against freeze damage is a vital part of a Facility Maintenance Program. A good freeze protection plan includes steps for inspection, preventative maintenance, and corrective maintenance prior to the beginning of cold weather conditions. This guide, provided by electric heater manufacturer BriskHeat, is designed to make the planning process easier for you.

Table of Contents

- Inventory Checklist for Pipe Lines and Valves That Need Heat

- Inventory Checklist for Containers Stored in Unheated Areas or Susceptible to Freezing

- Inventory Checklist for Large Permanent Tanks, Vessels, and Hoppers in Unheated Areas or Susceptible to Freezing

- Inventory Checklist for Roof and Gutter Deicing

- Inventory Checklist for Personal Safety / Slip Prevention

- Inventory Checklist for Damaged Heaters That Need to Be Replaced

- Inventory Checklist for Temporary De-icing Heaters

Contact M.S. Jacobs & Associates for more information on BriskHeat products. Reach them at 800-348-0089 or visit https://msjacobs.com.

Leading the Way in Instrumentation and Control Since 1945

M.S. Jacobs and Associates is a leading manufacturer's representative and distributor of industrial instrumentation and controls serving Western Pennsylvania, West Virginia, and New York State. Since 1945, the company's dedication to the industrial market has resulted in a broad offering of superior quality products for flow, level, pressure, and temperature measurement, as well as filtration products. M.S. Jacobs is known for solving tough applications and providing exceptional customer service with a team of highly trained outside and inside personnel.

MS Jacobs' products have contributed to the success of all major industrial markets, including power generation, chemical processing, pulp and paper, oil and gas production, water and wastewater treatment, and nuclear power generation. For over 70 years, M.S. Jacobs has continuously been there, providing support and service to their customers.

800-348-0089

Industrial Pressure and Temperature Switch Operating Basics

|

| Internal view of pressure switch. (Ashcroft) |

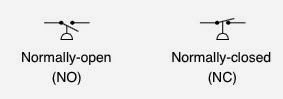

The opening and closing of the electrical circuit is done through electrical contacts. These electrical contacts are most often enclosed in their own housing in an assembly known as a microswitch. These contacts in the pressure switch are associated with the terms "normal", as in "normally open" or "normally closed". The normal status of a switch is the resting state with stimulation. A pressure switch will be in its normal status when it senses low or minimum pressure. For a pressure switch, normal status is any fluid pressure below the trip threshold of the switch.

|

| Switch Status Symbols |

|

| Explosion proof pressure switch. (Ashcroft) |

Deadband or (reset pressure differential) is one of the most important application considerations when applying a pressure switch. This setting determines the amount of pressure change required to reset the switch to its normal state after it has tripped. The differential pressure of a pressure switch should not to be confused with differential pressure switch, which actually measures the difference in pressure between two separate pressure ports.

|

| Temperature switch (Ashcroft) |

There are many, very important details that need to be considered when selecting and applying pressure and temperature switches. You must consider the electrical requirements (volts, amps, AC or DC), the area classification (hazardous, non-hazardous, general purpose, water-tight), pressure sensing range, temperature range, and material compatibility. It's highly recommended you consult with a process instrumentation expert for assistance.

Cashco Control Valves: Product Summary

|

| Cashco Ranger QCT |

Current models and designs are:

- Models 988 and 989 - Globe-style control valves with pneumatic spring-return actuator.

- Model 988-MB - a modified version of our Model 988 designed to handle hazardous fluids.

- Ranger QCT - universal control valve that offers 10 different trim combinations which can easily be changed without disturbing the packing, actuator, or positioner calibration.

- Model 521 - Globe-style control valve with sliding stem, bellows sealed, pneumatically actuated valves designed to achieve the ultimate in long-term corrosive chemical service.

- Premier EZO (short for easy opening) - Superb throttling characteristics and is designed to eliminate “popoff” flow surges.

- Model 987 - Precision globe-style “chemical valve” is the valve to handle hostile fluids and environments – as well as steam and water.

- Model 2296/2296HF - A stainless steel or bronze glove-style control valve available with pneumatic or electric actuators.

- Model 964 - A globe-style pneumatic control valve for general plant utility services.

Download a PDF version of the Control Valve Product Summary here or view the embedded document below.

800-348-0089

Magnetrol Pulsar Model R86 26 GHz Pulse Burst Radar Level Transmitter

The Magnetrol PULSAR Model R86 radar transmitter is based on pulse burst radar technology combined with equivalent time sampling circuitry. Short bursts of 26 GHz microwave energy are emitted and subsequently reflect- ed from the liquid level surface. Distance is first measured by the equation:

D = Transit time (round-trip)/2

Applications:

https://msjacobs.com

800-348-0089

D = Transit time (round-trip)/2

Applications:

- Media: Liquids and slurries; hydrocarbons to water- based media (dielectric 1.7–100, 1.4 in stillwell)

- Vessels: Most process or storage vessels up to rated temperature and pressure. Pits and sumps as well as glass-lined tanks.

- Conditions: Virtually all level measurement and control applications including process conditions exhibiting varying specific gravity and dielectric, visible vapors, high fill/empty rates, turbulence, low to moderate foam and buildup.

https://msjacobs.com

800-348-0089

Level Sensors for Corrosive Liquids

| ICON Levelpro plastic level sensors. |

Plastic level sensors are an excellent choice for corrosive liquid chemical applications. Plastics, unlike metals, do not corrode; however, they can deteriorate and swell if the correct plastic is not used.

ICON Process Controls offers its Levelpro plastic level sensors for continuous level indication, as well as plastic level switches for point level notification. There are many different factors to consider when selecting the right product for the application.

- Chemical Liquid?

- Concentration?

- Temperature?

With this information a material of construction for the level sensor can be selected. Next, it is important to understand other factors that contribute to the success or failure of the level sensor.

- Is there particulate with the liquid?

- Does the liquid create a film, or does it have a coating effect?

- Does the chemical produce foam?

- Is there sludge at the bottom of the tank?

- Is the liquid agitated?

Once the information pertaining to the chemical and the type of sensor technology (continuous or point) is determined, ICON can recommend the most suitable product for the application.

An excellent level sensor for corrosive liquids is the 100 Series submersible level sensor. The plastic level transmitter is available in PVC, PP and PVDF bodies, and comes standard with a corrosion-resistant PTFE jacketed cable and Kalrez O-rings. The 100 Series submersible level sensors incorporate a weighted body which ensures the sensor sits at the bottom of the tank. The plastic level transmitter has a ceramic sensing diaphragm that measures the head pressure of the liquid. These level sensors are not affected by foam, vapor, condensate or turbulence, making them an excellent choice for many different applications.

If the chemical produces sludge then ICON would recommend a non-contact level technology such as the Ultrapro ultrasonic level sensor, or the Proscan radar transmitter.

For clean liquids the CFL Series continuous float is a reliable and economical choice.

ICON also offers a complete line of plastic level switches for point level indication. These plastic switches are available in PVC, PP and PVDF materials, and the relay can be set to normally open or normally closed positions. Visit M.S. Jacobs at https://msjacobs.com for more information.

WIKA Phases Out PSD-30 and PSD-31 Pressure Switches, Replaced with PSD-4 Pressure Switch

The WIKA PSD-30 and PSD-31 pressure switches are currently being phased out, to be replaced with the newly updated PSD-4 pressure switch.

The model PSD-4 pressure switch represents the extensive development of the PSD-30 pressure switch. A high accuracy of 0.5 %, freely configurable output signals (PNP/NPN, 4-20 mA / 0-10 V), the 5:1 scalability of the analog output, in addition to outstanding self-diagnostics, make the PSD-4 an excellent automation solution for industrial machines, hydraulic systems, and pneumatic systems applications.

While the PSD-4 offers new features and functionality, pricing is comparable to that of the PSD-30 and PSD-31. This new pressure transmitter offers customizable features, such as allowing the user to select the switch type and output signal, while offering a 5:1 turndown ratio. Additionally, this transmitter is an economical solution for applications requiring local display with an analog output signal. The PSD-4 provides an upgrade in quality and customizability without negatively affecting budgets.

During development of the WIKA switch family a high value was placed on a robust design and the selection of appropriate materials suited to machine-building applications. For this reason the case and the threaded connection of the electrical connector are made from stainless steel.

For more information, contact M.S. Jacobs by visiting https://msjacobs.com or by calling 800-348-0089.

The model PSD-4 pressure switch represents the extensive development of the PSD-30 pressure switch. A high accuracy of 0.5 %, freely configurable output signals (PNP/NPN, 4-20 mA / 0-10 V), the 5:1 scalability of the analog output, in addition to outstanding self-diagnostics, make the PSD-4 an excellent automation solution for industrial machines, hydraulic systems, and pneumatic systems applications.

While the PSD-4 offers new features and functionality, pricing is comparable to that of the PSD-30 and PSD-31. This new pressure transmitter offers customizable features, such as allowing the user to select the switch type and output signal, while offering a 5:1 turndown ratio. Additionally, this transmitter is an economical solution for applications requiring local display with an analog output signal. The PSD-4 provides an upgrade in quality and customizability without negatively affecting budgets.

During development of the WIKA switch family a high value was placed on a robust design and the selection of appropriate materials suited to machine-building applications. For this reason the case and the threaded connection of the electrical connector are made from stainless steel.

For more information, contact M.S. Jacobs by visiting https://msjacobs.com or by calling 800-348-0089.

M.S. Jacobs: Dedicated to Service and Excellence in Process Control

M.S. Jacobs and Associates has been a leading manufacturer's representative and distributor of industrial instrumentation and controls since 1945. Expanding from its original focus on the steel industry, MS Jacobs services and supplies products in all major industrial markets, including power generation, chemical processing, pulp and paper, oil and gas production, water and wastewater treatment, nuclear power, pharmaceutical, institutional, and alternative energy.

Remote Power Where You Need It

Designed for rugged and remote operation, the PowerGen remote power generator provides reliable electrical power supply to the most demanding and mission-critical loads. Based on Qnergy’s no-maintenance and highly reliable PCK series Stirling engines, the generator package can work seamlessly with a variety of fuel supplies, including: natural gas, propane, ethane, biogas, and multiple associated gas streams. By means of its flexible and modular design, this generator package can be tailored to provide a broad range of power output architectures to meet the electrical requirements of each specific site load.

Designed for rugged and remote operation, the PowerGen remote power generator provides reliable electrical power supply to the most demanding and mission-critical loads. Based on Qnergy’s no-maintenance and highly reliable PCK series Stirling engines, the generator package can work seamlessly with a variety of fuel supplies, including: natural gas, propane, ethane, biogas, and multiple associated gas streams. By means of its flexible and modular design, this generator package can be tailored to provide a broad range of power output architectures to meet the electrical requirements of each specific site load.What Makes Qnergy PowerGen Your Remote Power Solution?

- Qnergy Stirling Engine

- No Maintenance

- Frictionless Piston

- Multiple Fuel Sources

- Zero Lubrication

- Enclosed System

- High Efficiency

Applications

- Artificial Lift

- Communication & SCADA

- Monitoring, Security & Safety

- Prime Power

- Renewable Hybrid

- Well Pad Automation

- Cathodic Protection (ICCP

Wireless Hazardous Area Access Point Enclosures, RF Enclosures, and Antennas

The HazaLynk™ Series by Analynk incorporates a wide selection of wireless hazardous area devices to suit a variety of industrial applications. The product line includes hazardous area antennas, hazardous area access point enclosures, and hazardous area RF enclosures that simplify the process of installing field instrumentation, while meeting code requirements for hazardous classified and explosive environments.

For more information, contact M.S. Jacobs by visiting https://msjacobs.com or calling 800-348-0089.

For more information, contact M.S. Jacobs by visiting https://msjacobs.com or calling 800-348-0089.

Why Choose Displacer Level Transmitters Over Differential Pressure Level Transmitters?

|

| DP level transmitter diagram. |

An example of a "tried and true" technology that was commonly used in the process automation industry is the DP (differential pressure) level transmitter. First introduced in the 1950s, DP transmitters measures the hydrostatic (head) pressure of a liquid in a tank or vessel and interprets this as level, based on the density/specific gravity of the liquid and programmed in by the user. A newer, alternative technology to DP transmitters is the displacer level transmitter, a device also based on specific gravity. While they both are dependent on specific gravity, they are significantly different in areas of installation, accuracy, and maintenance requirement.

Application/Calibration Considerations

|

| Displacer transmitter construction. |

- Infers Level vs. Direct Contact - DP transmitters use inferential measurement to determine level measurement from the hydrostatic pressure. Despite requiring the specific gravity variable having to be programmed into the transmitter electronics, the level displacer transmitter is in contact with the process media and the level measurement is direct.

- Time Required to Set up / Calibrate: DP transmitters requires time consuming and expensive calibration/re-calibration if any of the set-up parameters change or if the same DP transmitter is used on different materials in the same tank. Displacer transmitters only require two variables to be programmed (temperature and specific gravity), making it easier when running multiple products in the same tank. Furthermore, many displacer transmitters do not require liquid to be present for calibration. They are programmed (wet or dry) using software. A huge time and money saving over DP transmitters.

- Orientation and Tank Penetration - The physical mounting of DP transmitters is limited, which can in some situations can become downright problematic. DP transmitters require (2) side-mounted entry locations on the vessel or tank, with one having to be near the bottom. As a general rule, the fewer the entry points of a tank or vessel, the better (because of leakage). Tank bottom entries are all the more so concerning. Displacer transmitters are mounted to meet the requirements of the application and do not require a connection at the bottom of the tank.

|

| Displacer transmitter. (Magnetrol) |

- Consider Overall Installed Cost - While DP transmitters have a lower unit cost, adding ancillary components such as tubing and heat tracing can quickly "level" the installation cost playing field. Furthermore, don't discount the time cost savings when setting up, calibrating and re-calibrating displacer transmitters.

Temperature Range Considerations

- DP transmitters have a normal operating temperature of up to 250°F, with an upper limit of 650°F when special options are specified.

- Displacer transmitter can be used up to 850°F, very helpful particularly with level measurement in a hot oil separator application.

There are many options and variants to accommodate industrial level applications. Share your level application challenges with instrumentation specialists, leveraging your own knowledge and experience with their product application expertise to develop the most effective solution.

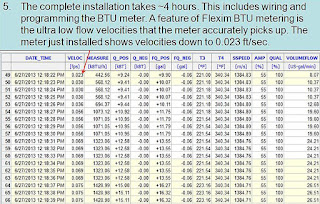

BTU Metering with Non-invasive, Clamp-on Ultrasonic Flow Meters

|

| BTU Metering for HVAC Energy Management |

We live in a society of buildings, each with a mapped out function. Most buildings are predominantly occupied by people, bringing a requirement to maintain temperature, relative humidity, and air quality at levels of suitable comfort for human occupants. The energy consumption involved with providing that level of comfort stands as a bold line item in the operating expense ledger for any building. That is where accountability and efficiency come in. It is in the building stakeholders' interest to have knowledge regarding rates and quantity of thermal energy usage, as well as efficiency measures of delivered output per unit of input energy.

|

| Installation of the BTU meter. Typically takes about 4 hrs. |

HVAC (Heating, Ventilation, Air Conditioning) primarily is an endeavor that generates and moves

thermal energy throughout an enclosed space. Commercially available technology now allows a building operator to accurately measure that movement of thermal energy throughout a system or building. The process is generally called BTU metering and has a number of justifiable benefits.

- Real time equipment performance measurement.

- Sub metering can indicate specific areas of consumption.

- Ability to directly bill multiple tenants in a single building for their thermal energy usage.

- Monitor and balance energy flows.

|

| Click for larger image. |

- No wear mechanism as part of the flow measurement unit

- Traceable accuracy of flow and temperature measurements

- Simple installation in new or retrofit applications without disruption to system operation

- Reliable and maintenance free operation

- Accurate measurement from near zero flow rate to maximum system flow

- Stable sensing with no zero drift

- Communications protocol to match building energy management system

- Large storage cache for data, in case of communication failure

- Common output signals, 4-20 ma or other, usable with selected ancillary equipment

Selecting the right equipment or instrumentation is the most important step along the path of adding measurement capability to increase efficiency. Without a solid stream of reliable data, useful decisions become difficult. Contact a product application specialist and share your goals and challenges. Leverage your own knowledge and experience with their product application expertise to develop an effective solution.

M.S. Jacobs & Associates

M.S. Jacobs & Associates is a leading manufacturer's representative and distributor of industrial instrumentation and controls in Western Pennsylvania, West Virginia and New York. MS Jacobs services and supplies products in all major industrial markets, including power generation, chemical processing, pulp and paper, oil and gas production, water and wastewater treatment, and nuclear power generation.

https://msjacobs.com

800-348-0089

https://msjacobs.com

800-348-0089

Load Cells in Process Measurement

|

| Low profile low cells applied for tank and vessel weighing and level indication. Image courtesy Minebea Intec |

Load cells are the key components applied to weighing materials in modern processing. Load cells are utilized throughout many industries in process weighing operations. In application, a load cell can be adapted for measurement of items from the very small to the very large.

In essence, a load cell is a measurement tool which functions as a transducer, predictably converting force into a unit of measurable electrical output. While many types of load cells are available, the most popular cell in multiple industries is a strain gauge based cell. These strain gauge cells typically function with an accuracy range between 0.03% and 0.25%. Pneumatically based load cells are ideal for situations requiring intrinsic safety and optimal hygiene and, for locations without a power grid, there are even hydraulic load cells, which function without need for a power supply. These different types of load cells follow the same principle of operation: a force acts upon the cell (typically the weight of material or an object) which is then returned as a value. Processing the value yields an indication of weight in engineering units. For strain gauge cells, the principle of deformation applies, where extremely small amounts of deformation, directly related to the stress or strain being applied to the cell, are output as an electrical signal with value proportional to the load applied to the cell. The operating principle allows for development of devices delivering accurate, precise measurements of a wide range of industrial products. Advantages of load cells include their longevity, accuracy, and adaptability to many applications, all of which contribute to their usefulness in so many industries and applications.

Share your process weighing challenges with product application specialists. Leverage your own knowledge and experience with their product application expertise to develop an effective solution.

Subscribe to:

Posts (Atom)