Sponsored by M.S. Jacobs & Associates, a manufacturer’s representative and distributor of industrial instrumentation, control valves & process controls. Located in Pittsburgh, Pa. and covering Western Pennsylvania, West Virginia, and New York. Representing top lines in pressure, temperature, level, flow, analytical instruments and industrial valves.

Telephone: 800-348-0089 or MSJacobs.com

Showing posts with label industrial control. Show all posts

Showing posts with label industrial control. Show all posts

US Power Grids, Oil and Gas Industries, and Risk of Hacking

A report released in June, from the security firm Dragos, describes a worrisome development by a hacker group named, “Xenotime” and at least two dangerous oil and gas intrusions and ongoing reconnaissance on United States power grids.

Multiple ICS (Industrial Control Sectors) sectors now face the XENOTIME threat; this means individual verticals – such as oil and gas, manufacturing, or electric – cannot ignore threats to other ICS entities because they are not specifically targeted.

The Dragos researchers have termed this threat proliferation as the world’s most dangerous cyberthreat since an event in 2017 where Xenotime had caused a serious operational outage at a crucial site in the Middle East.

The fact that concerns cybersecurity experts the most is that this hacking attack was a malware that chose to target the facility safety processes (SIS – safety instrumentation system).

For example, when temperatures in a reactor increase to an unsafe level, an SIS will automatically start a cooling process or immediately close a valve to prevent a safety accident. The SIS safety stems are both hardware and software that combine to protect facilities from life threatening accidents.

At this point, no one is sure who is behind Xenotime. Russia has been connected to one of the critical infrastructure attacks in the Ukraine. That attack was viewed to be the first hacker related power grid outage.

This is a “Cause for Concern” post that was published by Dragos on June 14, 2019.

“While none of the electric utility targeting events has resulted in a known, successful intrusion into victim organizations to date, the persistent attempts, and expansion in scope is cause for definite concern. XENOTIME has successfully compromised several oil and gas environments which demonstrates its ability to do so in other verticals. Specifically, XENOTIME remains one of only four threats (along with ELECTRUM, Sandworm, and the entities responsible for Stuxnet) to execute a deliberate disruptive or destructive attack.

XENOTIME is the only known entity to specifically target safety instrumented systems (SIS) for disruptive or destructive purposes. Electric utility environments are significantly different from oil and gas operations in several aspects, but electric operations still have safety and protection equipment that could be targeted with similar tradecraft. XENOTIME expressing consistent, direct interest in electric utility operations is a cause for deep concern given this adversary’s willingness to compromise process safety – and thus integrity – to fulfill its mission.

XENOTIME’s expansion to another industry vertical is emblematic of an increasingly hostile industrial threat landscape. Most observed XENOTIME activity focuses on initial information gathering and access operations necessary for follow-on ICS intrusion operations. As seen in long-running state-sponsored intrusions into US, UK, and other electric infrastructure, entities are increasingly interested in the fundamentals of ICS operations and displaying all the hallmarks associated with information and access acquisition necessary to conduct future attacks. While Dragos sees no evidence at this time indicating that XENOTIME (or any other activity group, such as ELECTRUM or ALLANITE) is capable of executing a prolonged disruptive or destructive event on electric utility operations, observed activity strongly signals adversary interest in meeting the prerequisites for doing so.”

M.S. Jacobs & Associates

M.S. Jacobs & Associates is a leading manufacturer's representative and distributor of industrial instrumentation and controls in Western Pennsylvania, West Virginia and New York. MS Jacobs services and supplies products in all major industrial markets, including power generation, chemical processing, pulp and paper, oil and gas production, water and wastewater treatment, and nuclear power generation.

https://msjacobs.com

800-348-0089

https://msjacobs.com

800-348-0089

M.S. Jacobs & Associates - Equipment Engineers

|

| Wastewater treatment is one of the many industrial sectors served by M.S. Jacobs |

The company's longevity and dedication to the industrial market has resulted in a broad offering of superior quality products for flow, level, pressure, and temperature measurement, as well as filtration products and valves. Everyone at MS Jacobs takes pride in the company's ability to solve tough applications and provide exceptional customer service with a team of trained outside sales engineers and inside customer service representatives.

MS Jacobs' Pittsburgh service center provides instrument calibration and repair for MSJ's complete line of products, as well as those of other manufacturers. The company carries factory authorization for repair of numerous manufacturers' industrial process instrumentation products. The service center also provides custom assembly of instruments and other gear to meet customer requirements. Completed assemblies are tested and certified prior to shipment.

Reach out to MS Jacobs & Associates for the products and services that move your process instrumentation and control projects toward a successful completion.

Get To Know MS Jacobs & Associates for Industrial Process Control Instruments and Equipment

|

| MS Jacobs serves the electric power generation industry, as well as chemical, oil and gas, water and wastewater |

The company's longevity and dedication to the industrial market has resulted in a broad offering of superior quality products for flow, level, pressure, and temperature measurement, as well as filtration products and valves. Everyone at MS Jacobs takes pride in the company's ability to solve tough applications and provide exceptional customer service with a team of trained outside sales engineers and inside customer service representatives.

MS Jacobs' Pittsburgh service center provides instrument calibration and repair for MSJ's complete line of products, as well as those of other manufacturers. The company carries factory authorization for repair of numerous manufacturers' industrial process instrumentation products. The service center also provides custom assembly of instruments and other gear to meet customer requirements. Completed assemblies are tested and certified prior to shipment.

Reach out to MS Jacobs & Associates for the products and services that move your process instrumentation and control projects toward a successful completion.

Oxygen or High Purity Service Valve Preparation

|

| Industrial Ball Valve Courtesy Marwin Valve |

Odorless and colorless, oxygen is concentrated in atmospheric air at approximately 21%. While O2, by itself, is non-flammable, it vigorously supports combustion of other materials. Allowing oils or greases to contact high concentrations of oxygen can result in ignition and possibly explosion. Oxygen service preparation of an industrial valve calls for special cleaning processes or steps that remove all traces of oils and other contaminants from the valve to prepare for safe use with oxygen (O2). Aside from the reactive concerns surrounding oxygen, O2 preparation is also used for applications where high purity must be maintained and valves must be free of contaminants.

Gaseous oxygen is noncorrosive and may be used with a variety of metals. Stainless steel, bronze and brass are common. Liquid oxygen presents unique challenges due to cryogenic temperatures. In this case, valve bodies, stems, seals and packing must be carefully chosen.

Various types of valves are available for oxygen service, along with a wide array of connections, including screwed, socket weld, ANSI Class 150 and ANSI Class 300, DIN PN16 and DIN PN40 flanged ends. Body materials include 316 stainless steel, monel, bronze and brass. Ball and stem material is often 316 stainless steel or brass. PTFE or glass filled PTFE are inert in oxygen, serving as a common seat and seal material employed for O2 service.

Common procedures for O2 service are to carefully deburr metal parts, then meticulously clean to remove all traces of oil, grease and hydrocarbons before assembly. Valve assembly is performed in a clean area using special gloves to assure no grease or dust contaminates the valve. Lubricants compatible with oxygen must be used. Seating and leakage pressure tests are conducted in the clean area, using grease free nitrogen. Specially cleaned tools are used throughout the process. Once assembled, the valves are tested and left in the open position. A silicone desiccant pack is usually inserted in the open valve port, then the valve ports are capped. A warning label about the desiccant pack's location is included, with a second tag indicating the valve has been specially prepared for oxygen service. Finally, valves are individually sealed in polyethylene bags for shipment and storage. Different manufacturers may follow slightly differing protocols, but the basics are the same. The valve must be delivered scrupulously contaminant free.

The O2 preparation of valves is one of many special production variants available to accommodate your special application requirements. Share your valve requirements and challenges with a valve specialist to get the best solution recommendations.

Unique Cybersecurity Challenges For Industrial Control Systems

|

Industrial control systems have special

cybersecurity aspects.

|

A quote from article...

“Cyber incidents have been defined by the US National Institute of Standards and Technology (NIST) as occurrences that jeopardize the confidentiality, integrity, or availability (CIA) of an information system.”

ICS cybersecurity extends beyond preventing malicious outside intruders from gaining access. It is an important part of maintaining the overall operating integrity of industrial processes. A holistic approach is advocated to identify physical risk factors to the process and its componentry (subject of a previous blog posting), as well as vulnerabilities that may prevent exploitation by unauthorized parties. Weiss goes on to describe the role and qualifications of the ICS Cybersecurity Expert, essentially an individual that can function effectively as an IT cybersecurity tech with the added skills of an industrial control systems expert.

A synopsis of attack events is provided in the article, with the author’s conclusion that not enough is being done to secure industrial control systems and the risk exposure is substantial in terms of potential threats to personnel, environment, and economy. By providing your name and email address, you can obtain the white paper from the ISA website. Your time spent obtaining and reading the article will be well spent.

For any specific information or recommendations regarding our products and cybersecurity, do not hesitate to contact us directly. We welcome any opportunity to help our customers meet their process control challenges.

Cavitation Induced by a Control Valve - Demonstrated

Consider a generic industrial fluid process control operation. There are pumps, valves, and other components installed in the process lines that, due to their interior shape or their function, cause changes in the fluid motion. Let's look specifically at control valves and how their throttling operation can create conditions able to greatly impact the valve itself, as well as the overall process.

Fluid traversing a control valve can undergo an increase in velocity when passing the constriction presented by the valve trim. Exiting the trim, fluid then enters the widening area of the valve body immediately downstream with a decrease in velocity. This change in velocity corresponds to a change in the kinetic energy of the fluid molecules. In order that energy be conserved in a moving fluid stream, any increase in kinetic energy due to increased velocity will be accompanied by a complementary decrease in potential energy, usually in the form of fluid pressure. This means the fluid pressure will fall at the point of maximum constriction in the valve (the vena contracta, at the point where the trim throttles the flow) and rise again (or recover) downstream of the trim.

Here is where cavitation in control valves begins.

If the fluid being throttled is a liquid, and the pressure at the vena contracta is less than the vapor pressure of the liquid at the flowing temperature, portions of the liquid will spontaneously vaporize. This is the phenomenon of flashing. If, subsequently, the pressure of the fluid recovers to a level greater than the vapor pressure of the liquid, any flashed vapor will rapidly condense, returning to liquid. This collapse of entrained vapor is called cavitation.

Flashing, the generation of vapor bubbles within the liquid, will precede and set the stage for cavitation. When the flashed vapor bubbles condense to liquid they often do so asymmetrically, with one side of the bubble collapsing before the rest of the bubble. This has the effect of translating the kinetic energy of the bubble’s collapse into a high-speed “jet” of liquid in the direction of the asymmetrical collapse. These liquid “microjets” have been experimentally measured at speeds up to 100 meters per second (over 320 feet per second). What is more, the pressure applied to the surface of control valve components in the path of these microjets can be intense. An individual microjet can impact the valve interior surfaces in a very focused manner, delivering a theoretical pressure pulse of up to 1500 newtons per square millimeter (1.5 giga-pascals, or about 220000 PSI) in water. In an operating fluid system, this process can be continuous, and is known to be a significant cause of erosive wear on metallic surfaces in process piping, valves, pumps and instruments. As the rapid change in pressure takes place, the bubbles (voids in the liquid) collapse (implode), and the surrounding metal surfaces are repeatedly stressed by these implosions and their subsequent shock waves.

Consequences for control valves, as well as for the entire control process, vary and are often destructive. They may include:

- Loud noise

- Strong vibrations in the affected sections of the fluid system

- Choked flow caused by vapor formation

- Change of fluid properties

- Erosion of valve components

- Premature destruction or failure of the control valve

- Plant shutdown

The solution lies in minimizing the potential for cavitation to occur through proper valve selection and sizing, along with coordinating operating characteristics of pressure drop inducing components with the total system performance. One valve manufacturer's recommendations are summed up in four basic approaches.

- Avoidance of cavitation through proper valve selection. Use a valve with a rated liquid pressure recovery factor greater than that required for the application. Some applications may be suitable for the use of an orifice plate downstream of the valve.

- Cavitation Tolerant Components capable of withstanding limited amounts of cavitation without excessive wear. Increased flow noise is likely to accompany this route.

- Prevention of cavitation through the use of valve trim design that reduces pressure in several steps, avoiding excessive flashing. These valves can be expensive, but their effectiveness makes them an alternative worth considering.

- Containment of the harmful effects of limited to moderate cavitation through trim designs that eliminate contact of the fluid with metal surfaces which are more susceptible to damage.

Share your requirements and application challenges with a valve specialist and gain insight through their recommendations. Combining your process knowledge with their product application expertise will yield a great solution.

Innovations In RTD Signal Conditioning - One Manufacturer's Compilation

|

| RTD Signal Conditioning Units Courtesy Acromag |

Some of us have used RTDs in our process designs for many years, maybe without recognizing the innovations that have come about in the signal conditioning portion of our installations. One manufacturer of industrial signal conditioning equipment, Acromag, has compiled the ten most significant recent advances in RTD signal conditioning. I have included their white paper below.

Browse the paper, as it is brief and informative. You will likely see a few improvements of which you were unaware. Share your temperature measurement and signal conditioning challenges with an application specialist. Combining your process experience with their product application expertise will produce positive solutions.

Ethernet I/O Modules Provide Connectivity Advantages

|

| Industrial Ethernet I/O Modules Courtesy Acromag |

- Point to point wiring from each measurement device to the control point.

- Wireless linkup from measurement location to controller.

- Wired network connection between measurement and control devices.

Each of these connection topologies has particular attributes which may better suit a particular application. For a wired network scheme, Acromag has designed a line of I/O modules that make installation and configuration a smooth operation. Helpful features include:

- Power wiring options that allow back connected bus power or top mounted screw terminals. You can even provide primary and backup power sources to the two connections.

- Front facing screw terminals for connections make status checking of inputs a simple operation with your digital volt meter.

- Modules are rail mounted and can be placed immediately adjacent to one another for high density installation.

- Modules have a built in webpage for display of operational information. Configuration is accomplished using a front mounted USB port.

- Operable in temperatures -40 to +70 deg. Celsius.

- Two Ethernet ports on each unit allow modules to be daisy chained, reducing or negating need for local hubs.

- Acromag's Priority Channel Technology assures that data update frequencies are maintained, regardless of other network traffic.

The short video below provides additional detail on the useful features of the Acromag line of industrial Ethernet I/O modules. Watch the video. Share your process measurement and control connectivity challenges with a sales engineer specializing in industrial Ethernet I/O. Combine your process knowledge with the state of the art product knowledge of a product specialist for the best solutions.

Flexible Hazardous Gas Detection Monitoring System

|

| Sentry IT Controller For Hazardous Gas Detection Monitoring Courtesy Sierra Monitor |

Properly designing a hazardous gas monitoring system starts with identifying the target elements and their sources. Gaseous hazards can generally be divided into three general classes, all of which can be specifically targeted with a properly configured gas monitoring system.

- Combustible gas concentrations subject to ignition and explosion.

- Toxic gas with inherent personnel risk.

- Insufficient oxygen levels to support human respiration.

The best overall system configuration can be achieved through a combination of detectors, communications, and response that will provide accurate sensing of the target hazard, reliable and predictable transmission of information, and preconfigured response when alarm limits are triggered. Some product features for the detector monitor that may prove useful in a well specified installation:

- A means to non-intrusively calibrate all sensors at the same time

- Ability to diagnostically monitor connected sensors for performance.

- Provision of an easily operable interface for users.

- Battery backup to maintain operation during a power outage.

- Network and protocol compatibility with a range of industry accepted standards.

- Simple means to upgrade operating software.

- Compatibility with detection devices from a broad array of sources.

- Input capacity for more sensors than your current requirement.

I have included a bulletin describing such a unit, manufactured by Sierra Monitor. Browse the document and contact a hazardous gas detection application specialist to get more details and discuss your hazardous gas detection challenges. The best solutions come from combining your process knowledge and experience with that of a product application specialist.

Rotameters For Flow Measurement - Selecting the Right One

|

| Industrial Rotameter Flow Meters Courtesy King Instrument |

Rotameters are very specific to each flow measurement application. It's important that you know your fluid properties, ambient conditions, connection and readability specifications.

Start with these selection parameters:

- Desired flow rate range

- Fluid specific gravity

- Ambient temperature

- Operating and maximum pressure

- Line size

- Connection type

- Connection orientation

- With or without a valve

- Material requirements to accommodate fluid

- Scale units of measure. Smallest scale divisions needed.

For each application, it's advisable to work closely with a sales engineer to gather all the needed information and coordinate the product selection process.

Consult with a product specialist about your flow measurement application. A combination of your process knowledge and their product expertise will produce the best solution.

Here are some things to consider for potential rotameter applications:

- Simple design and operation provide a modest cost solution.

- No external power is required for operation. Inherent fluid properties and gravity are used to measure flow rate.

- Clear glass used for the measuring tube is highly resistant to thermal shock and corrosion.

- Instrument orientation must be vertical, with fluid flowing upward.

- Scale graduations are accurate for a given substance at a given temperature, making the devices application specific.

- Operation of the rotameter may be impacted by changes in the viscosity of the fluid. Consult with a product and application specialist to explore your application.

- Direct flow indication provides resolution that may not be as good as some other flow measurement methods.

- Visual reading of the scale is subject to uncertainty due to float oscillation, parallax, and location on the scale.

- Make sure the fluid turbidity, or another fluid characteristic will not obscure the visibility of the float.

Consult with a product specialist about your flow measurement application. A combination of your process knowledge and their product expertise will produce the best solution.

Application Suitability of Ultrasonic Flowmeters

|

| Ultrasonic Liquid Flow Measurement System Courtesy Flexim America |

Ultrasonic flow meters measure flow indirectly by calculating transit time of a sound wave through, or reflecting from, a flowing fluid. The velocity of the fluid has an impact on the transit time, from which a flow rate can be calculated. Attributes of ultrasonic flow measurement that may determine suitability for a particular application include:

- Transducers can be clamped on exterior pipe surface where measurement is needed.

- Non intrusive measurement technology prevents contact between media and measuring elements.

- No significant pressure drop associated with measuring device installation.

- Reduced leak potential.

- No moving parts.

- Comparatively higher cost than some other technologies.

- Fluid characteristics must be well known for proper application.

- Pipe cross section must be completely filled by media to acquire accurate flow measurement.

Learn more about this process measurement and control technology in the product detail sheet below. Consult with a product application specialist for more detailed product information and tips on how to best apply ultrasonic flow meters to your process.

Avoid Process Downtime With Five Device Protection Considerations

|

| Industrial Process Instruments |

Process control is achieved through the measurement of various conditions and application of regulated adjustments to the process inputs to deliver a desired output. Process variable measurement serves as the input to the control system. In the industrial sphere, it is common to see devices used for the measurement and transmission of temperature, pressure, flow, mass, level, and electrical parameters like voltage, current, capacitance and more. Regardless of what is being measured, there are three common characteristics:

- Device - A combination of a sensor and a translator that together detect some physical condition of the process and produce an output signal that can be correlated to the process condition.

- Location - The device will have a location that is dictated by the process construction and arrangement. Device locations have a tendency to be inflexible.

- Signal transmission path - Unless the control element is integral to, or adjacent to, the measurement device, there will be some path over which the measurement signal must travel to reach an associated control element.

Looking at these three elements for each measurement point, consider the five risk categories below in evaluating what you can do to safeguard your process measurement instrumentation. It's advisable to open a conversation with an experienced application specialist and freely discuss your concerns. Gathering additional input from various experienced sources will help you determine how extensive your protective measures should be to deliver a balance between cost and the probability of certain adverse events.

- Local Weather: There is local weather data available for almost every place on the planet. Take the time to procure reliable data and examine the distribution of temperature, humidity, precipitation, and wind conditions throughout all seasons. Clearly, if portions of the process are located outdoors, extreme local weather conditions will need to be accommodated. Even if your process is located indoors, local weather information is important if the process is to operate continuously. Consider whether an indoor process must continue to operate, even if the building HVAC system fails and indoor conditions begin to be impacted by outdoor conditions. Also, depending upon the design of the building climate control system, changing outdoor conditions can have a noticeable and possibly significant impact on the indoor air conditions.

- Process Generated Conditions: There may be specific aspects of your process that produce occurrences of vibration, pressure spike, electrical interference, or a host of other aberrations that may affect the proper operation of measurement devices. Know your process....really know it. Protect instrument sensors from potentially damaging transients and other process conditions that can be reasonably expected to occur. Device location relative to sources of electrical interference, elevated temperature, vibration, shock, and other transient conditions should be considered.

- Security: Your design goal should be to achieve a very high level of certainty that the signals generated by the measurement devices are uninterrupted and reflect the actual process conditions. There are two cases I always consider for security. The first is cyber, which applies in the case of a process measurement device network connection. Necessary steps should be taken to thwart an attempt to breach the network and detect unusual conditions that might indicate an invader's attempt to manipulate the process. My second case is related to device access by those without proper knowledge, training, or permission. Protection from these threats will likely involve a combination of physical barriers and procedures.

- Physical Contact: Industrial settings are, well, industrial. Large, heavy, irregular, unwieldy, and sharp things can sometimes be moved through areas occupied by process measurement gear. Technicians with carts, tools, and materials frequently pass through process areas to do their work. Protecting equipment and instruments from damaging contact pays dividends for the life of the installation. Consider, in your design and layout, the proximity of instruments to areas of traffic. If applicable, also consider areas overhead. The level of protection will need to be balanced with the need for access by qualified individuals for service, maintenance, calibration, and observation, as applicable.

- Moisture: Electronics are a mainstay of modern measurement instrumentation. Clearly, liquid moisture must be kept from contact with electronic circuits. Vaporous moisture will find a path to the internals of your electronic devices. This vapor, which is present in considerable levels in almost every indoor and outdoor environment, can condense when the right conditions are present. It is imperative that enclosures, conduit, boxes, fittings must be provided with barriers to moisture entry and/or a reliable means to automatically discharge accumulated liquid moisture before damage occurs.

There is much to think about in the realm of device protection. Balancing the costs of protection, the impact of protective measures on the ability to service and operate the process, and the risk involved with process failure or shutdown requires the application of technical expertise, experience, and sound practical judgement. Draw information and opinion from multiple sources, including sales engineers. Combine their product application knowledge with your process expertise to make good decisions.

Application Advantages of Intrinsically Safe Barriers

|

| 2-Wire Transmitter in Hazardous Area With Intrinsic Safety Barrier Courtesy Ronan Engineering Company |

Industrial process measurement and control operations have few boundaries. Land, sea, air, light, dark, dry, wet, hot, cold, indoor, and outdoor environments. Did I mention potentially explosive? Well, there is that, too.

If your experience was anything like mine, it is likely that your first project involving a hazardous area really drove home the fact that you are working at a very serious endeavor. In addition to quality problems or downtime resulting from equipment failure, now you add "the place blows up" to the list of possible outcomes. It's sobering, and not the type of situation where you have the option of real world testing. You need to be right the first time. Every remotely possible source of ignition must be considered and rendered harmless.

One way to provide the necessary level of safety is through the use of explosion proof enclosures, conduit, fittings, and other devices. By their nature, these items are designed to contain an internal explosion and provide for the expansion and cooling of the ignited gases into the surrounding atmosphere. The expansion cools the hot gas to a temperature safe for venting from the enclosure into the hazardous area without causing an ignition.

There is a good solution for measurement and control circuits requiring only low power levels. Intrinsically safe circuit designs employ barriers that allow power limited connections between devices in a hazardous zone and those in a non-hazardous zone. Intrinsic safety relies on the limiting of available energy in the system to a level that will not ignite a hazardous atmosphere (explosive gas or dust). Without significant energy storage, and ensuring that only low voltages and currents enter the hazardous area, intrinsically safe design removes the circuit as a possible ignition source. Where it is possible to utilize an intrinsically safe circuit, there are some advantages over using an explosion proof design.

- Absence of explosion proof enclosures enhances the accessibility of system components.

- Personnel safety is increased with low voltage operation.

- Standard wiring methods and materials may be used. No explosion proof conduit, boxes, fittings.

- Calibration and maintenance can be performed with the system in operation.

- Special skill levels required by an explosion proof design are not required with intrinsically safe design.

A primary device in an intrinsically safe circuit will be the barrier. The intrinsic safety barrier forms the border between the hazardous and non-hazardous areas. There are other design considerations, all of which you should discuss with knowledgeable application specialists. I have included a document below from Ronan Engineering Company, a manufacturer of intrinsic safety barriers. It provides some additional useful information, including a listing of the many I/O applications where the barriers can be employed.

Thermal Mass Flow Meters - Mature Technology With Modern Application

|

| Configurations of Thermal Mass Flow Meters Courtesy Thermal Instrument Co. |

Potential advantages of thermal mass flow technology for industrial process measurement and control:

- Provides true mass flow reading using a single instrument

- Not significantly affected by fluid pressure or temperature

- Moderate comparative cost

- No moving parts

- Minimal restriction of flow introduced by sensor

Typical applications for thermal mass flow meters:

- Landfill gas outflow measurement

- Compressed air systems

- Gas distribution in semi-conductor manufacturing

- Beverage carbonation

- Tablet coating and compression in pharmaceutical industry

- Flare gas measurement in oil and gas industry

- Natural gas flow to boilers, furnaces, and other consuming equipment

Thermal mass flow sensors have attributes making them very suitable for a family of applications. Like all measurement technologies, there are also areas of caution in their application. Any measurement technology must be properly applied in order to obtain reliable results. Talk to a sales engineer about your flow measurement ideas and applications. Combining your process expertise with the knowledge of a product application specialist will produce good results.

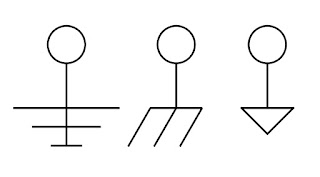

Are You Well Grounded on Grounding? - Part 3

|

| Electrical Drawing Symbols for Ground |

The white paper that I have included below was produced by the folks at Acromag, a world class manufacturer of signal conditioners and other industrial I/O devices. They have done a fantastic job of presenting technical subject matter in a compact and very understandable form. The subjects covered in the series include:

- Ground as protection

- How a ground fault circuit interrupter (GFCI) works

- Ground as a voltage stabilizer and transient limiter

- Tips on improving safety and signal integrity

- The importance of circuit grounding

- Description of the US AC power system and its use of earth ground

Product specialists are always on hand to discuss and solve your process measurement and control issues. Combine the process knowledge of the on site stakeholder with the product and application expertise of the professional sales engineer to produce the best outcomes.

Are You Well Grounded on Grounding? - Part 2

|

| Drawing Symbols for Ground |

Acromag, a manufacturer of input and output devices for industrial control systems, has produced a three part series of white papers that provide readable, non-technical descriptions of various aspects of electrical grounding and its relationship to safety and operational integrity. The subjects covered in the three part series include:

- Ground as protection

- How a ground fault circuit interrupter (GFCI) works

- Ground as a voltage stabilizer and transient limiter

- Tips on improving safety and signal integrity

- The importance of circuit grounding

- Description of the US AC power system and its use of earth ground

You can find the initial installment on our previous blog post, and the third installment follows this blog post. All three parts are recommended reading for anyone, but stakeholders in process measurement and control will benefit from refreshing and enhancing their understanding of this important subject. It is a quick read and presents technical subject matter in a way that can be comprehended by anyone.

Product and application specialists are always eager to hear about your application issues and questions. Never hesitate to contact them. Your process knowledge, combined with the product and application familiarity of a professional sales engineer, will generate good outcomes.

Big Signal Loop? Consider Using a Splitter.

|

| Industrial Signal Transmitters Courtesy Acromag |

In the cabled process measurement and control world, the 4 to 20 milliampere signal is generally considered the standard for transmitting analog control and measurement signals over any distance.

There is an immense array of instrumentation and controllers available for use with 4-20 ma signals, so expertise in routing and delivering those signals should be part of your process M&C skill set.

Like just about everything else, routing 4-20 ma signals presents its own set of challenges that require some thought and planning to overcome. Electrical interference is always a concern and must be prevented from impacting the operation of measurement and control devices. Additionally, there must be sufficient power in the signal loop to accommodate the resistance load of connected devices. There are other considerations, but I'm going to focus on these two.

One scenario that can present significant issues is multiple devices requiring connection to the same signal, but with great distance between them. A simple solution can be implemented using an isolated signal splitter.

Features of these units making them an attractive, single box, solution:

- One 4-20 ma input channel for the measuring or controlling device.

- The input signal is retransmitted as identical isolated 4-20 ma signals

- Galvanic isolation from input to output

- Isolation between channels for safety and increased noise immunity. Fault in one output channel does not impact the operation of the other channels.

- Reliable operation in industrial environments, with protection from RFI, EMI, ESD, and surges.

- Low radiated emissions in accordance with CE requirements.

- DIN-rail mounting of the unit

- Plug-in terminal blocks

If you have a very long signal loop, connecting multiple devices, consider breaking the devices into two groups that may allow for a substantially shorter cable length for each group. Connect each group to one of the isolated outputs of the splitter, giving each group of instruments the identical signal without the risks or impractically of an excessively long cable run.

There are other devices available that may combine special characteristics that solve your signal transmission challenges. Contact a product specialist and discuss your existing or anticipated project requirements. I continually urge engineers to take their process expertise, combine it with the extensive product knowledge of a professional sales engineer, and produce the best possible outcome.

Electric Power Where There Is No Grid

Humankind's quest to continually do more than has been done before takes engineers and technicians, along with their equipment, instruments, and other gear, to all corners of the Earth. Wherever the project goes, electric power will be needed to power it. Unless the needs are short term and very small, a reliable means to produce electric power on site must be put in place to operate equipment, instruments, and other systems necessary for the installation to function as needed.

The potential applications for remote power are vast, ranging from simple land based off-grid locations to ocean platforms, even polar stations. Industrial process measurement and control is found everywhere, which means that sometimes you need to provide the power to operate your own measurement and control equipment. To some, this will be a new challenge to their project management, design, or implementation skills.

Gentherm Global Power Technologies is not only the world leader in thermoelectric generation for remote power systems, they also employ solar and engine driven generator sets in their turnkey systems that can be specifically tailored to your application and installation site. As providers of a wide range of generation technologies, Gentherm is in a unique position to propose the most reliable and cost effective solution for each particular project. Become familiar with this company. You never know where your next project may be located.

A short video, included below, will get you started. You can also contact a product specialist to discuss any aspects of applying the technology.

The potential applications for remote power are vast, ranging from simple land based off-grid locations to ocean platforms, even polar stations. Industrial process measurement and control is found everywhere, which means that sometimes you need to provide the power to operate your own measurement and control equipment. To some, this will be a new challenge to their project management, design, or implementation skills.

Gentherm Global Power Technologies is not only the world leader in thermoelectric generation for remote power systems, they also employ solar and engine driven generator sets in their turnkey systems that can be specifically tailored to your application and installation site. As providers of a wide range of generation technologies, Gentherm is in a unique position to propose the most reliable and cost effective solution for each particular project. Become familiar with this company. You never know where your next project may be located.

A short video, included below, will get you started. You can also contact a product specialist to discuss any aspects of applying the technology.

Practical Considerations for Thermocouple Selection

|

| Industrial Thermocouples, Fixed Bend Bayonet Type Courtesy Wika |

Thermocouple sensor assemblies are available with almost countless feature combinations that empower vendors to provide a product for every application, but make specifying a complete unit for your application quite a task. Let's wade through some of the options available and see what kind of impact each may have on temperature measurement performance.

- Thermocouple Type: Thermocouples are created using two dissimilar metals. Various metal combinations produce differing temperature ranges and accuracy. Types have standard metal combinations and are designated with capital letters, such as T, J, and K. Generally, avoid selecting a type that exhibits your anticipated measurements near the extremes for the type. Accuracy varies among thermocouple types, so make sure the accuracy of the selected type will be suitable.

- NIST Traceability: This may be required for your application. The finished thermocouple assembly is tested and compared to a known standard. The error value between the thermocouple shipped to you and the standard are recorded and certified. The certified sensor assembly will be specially tagged for reference to the standard.

- Junction Type: If your sensor will be contained within a tube or sheath, the manner in which the actual sensor junction is arranged is important. The junction can be grounded to the sheath, electrically insulated from the sheath (ungrounded), or protruded from the sheath (exposed). If your process environment may subject the sensor assembly to stray voltages (EMF), it may be wise to stay away from a grounded junction, even though it provides fast response to a change in temperature. Exposed junctions provide very quick response, but are subjected to potential damage or corrosion from surrounding elements. The ungrounded junction provides protection within the enclosing sheath, with a slower response time than either of the other two junction types. When using ungrounded junctions, keep the mass and diameter of the sheath as small as might be practical to avoid overdamping the sensor response.

- Probe Sheath Material: This applies to assemblies installed in a tube or sheath which houses and protects the sensor junction and may provide some means of mounting. Material selections include a variety of stainless steel types, polymers, and metals with coatings of corrosion resistant material to suit many applications. Make sure the sheath material, including any coatings, will withstand the anticipated temperature exposure range.

- Probe Configuration: Sheath tube diameter and length can be customized, along with provisions for bends in the tube. Remember that as you increase the mass around the junction, or increase the distance of the junction from the point of measurement, the response time will tend to increase.

- Fittings and Terminations: There are innumerable possibilities for mounting fittings and wiring terminations. Give consideration to ease of access for service. How will the assembly be replaced if it fails? Are vibration, moisture, or other environmental factors a concern? What type of cable or lead wires would be best suited for the application?

|

| Industrial Thermocouples, Showing Various Termination Options Courtesy Wika |

Your options are so numerous, it is advisable to consult a manufacturer's sales engineer for assistance in specifying the right configuration for your application. Their product knowledge and application experience, combined with your understanding of the process requirements, will produce a positive outcome in the selection procedure.

Subscribe to:

Comments (Atom)